If you dream it, we'll make it!

|

1906 Trentham Road

KYNETON 3444 VIC AUSTRALIA |

THE DIAMOND T950 RESTORATION STORY

BY IAN LEE

In the late 1950’s the two trucks on my wish list were the new B Series Mack for style and with awesome diesel power they were the highway kings of the period. The Queen with its outstanding jewelled bonnet side vents and top performing petrol engine was the Diamond T 630 and a lady you could love forever. Today few examples remain and the news of a skeleton which was a must to see, then the remains of a second larger one and the bits of a third, and a youthful memory came flashing back

The remains of a long wheel base heavy duty Cummins powered Diamond T at Toowoomba looking like a lost cause, and waiting for a new life down south.

Returning home from Queensland with the rusted bones of a 630, a fair cabin in the centre and rusting remains of a long bonnet, Cummins powered Diamond up front and a reberth was now a reality. Then the romantic memories were overtaken by, 1950 and early 1960 facts, that the power and gearing at best did 80 kms per hour loaded on flats and long steep climbs,

Cliff Young walked faster!

Brakes and steering were primitive at best and few driver comforts, and not suited to today’s traffic.

Diamond T have a long history of sharing components with International, so a new transplant seemed a logical step.

Diamond T have a long history of sharing components with International, so a new transplant seemed a logical step.

International 2350G with compatable Cummins 6CTA 216Kw engine, Allison WT-MD 3060P gear box, Meteor 9000Kg rear axle with 4.89 ratio diff, 419 + 178 mm brakes, Hendrickson HAS 200 airbag rear suspension, front axle Spicer 1.14, 6.350Kg front axle, 419x152mm brakes with long tapered leaf springs, 5046 sqm radiator, Sheppard M100 power steering with adjustable steering column, 10 stud West Coast polished aluminium wheels which all bolted neatly to the Diamond T chassis.

First cabin fit up. Air bags now mounted with twin exhaust smoke splitters. Later changed as we decided to fit a 60” sleeper and not happy with cabin size. Its not proportional to the bonnets.

Cabin stripped for repair and enlargement

Floor extension to cabin floor with all rusted section replaced and cabin mounting frame, later repaired and re fitted.

Big Boy roof and back extension to make cabin look with bonnet and it makes a huge improvement to leg room

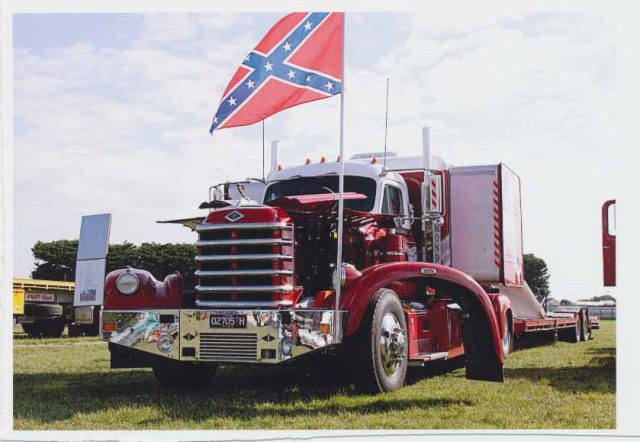

The old and the new interwoven special big boy cabin, bonnets and grille, mounted on separate pivoting chassis with air bag under cabin, dual vertical smoke splitters, deep Texas bumper bar, twin Donaldson air cleaners, special deep dash…. Stage one now complete

Stage 2.

We decide to fit a 60” sleeper this includes further cabin modification to give walk through access of 1400x930 to sleeper

And we lower floor between seats in cabin to improve entry and fit a foot well in the sleeper entry and in kitchen & toilet area to allow 1800 head clearance in sleeper.

Our efforts start to pay off including lowering the air cleaners. The fold out mudguards are now working, Alan the master of body work modifications makes the final adjustments ready for stripping an final painting.

The chassis is finally in roll over jig and Richard grit blasts ready for undercoat and final fit up of all bracket for final coating as a complete unit

All the chassis bits grit blasted and undercoated ready for final fitting and painting in roll over jig.

It’s a great relief to finally see the shiny top coat.

Day by day all the work and planning are paying off.

The right side looks right

Finally, final assembly starts to take place.

After many weeks of effort by Alan to hand make a rebate in cabin to match the original, the bed slide out finally fits in and out as planned

Tim does final fit up of axle mounted low profile rear mud guards

Toilet recess into foot well to give 1850 head clearance on kitchen side with fold down basin and vanity mirror

Standard single bed with drawers. Hanging space at rear in open location.

Kitchen slide out in open location with microwave and drawer type fridge.

Dash and convenient controls. Adjustable steering column up and down and in and out. Auto control pad in dash. Slide out tray lower dash.

Switches, warning lights, radio/CD player, UHF, Sat. Nav. And reversing monitor above driver.

I must thank the following people for making my plan the real thing, especially The Tylden Team, including Alan Barta, who hand made the entire engine bay including modifying the guards, extending and raising the cabin, building the sleeper extensions and interior and custom hinged sides, moulding the mirror brackets for casting and a hundred other bits.

To Tim Turner for the mechanics, ABS brakes, painting and a list too long to include.

Outside contractors, Vereker Bros for cabin and sleeper painting, Tylden Trim for the interior linings, Andrew Kennedy for painting the smiling princess, and a host of other people for a host of services.

To Tim Turner for the mechanics, ABS brakes, painting and a list too long to include.

Outside contractors, Vereker Bros for cabin and sleeper painting, Tylden Trim for the interior linings, Andrew Kennedy for painting the smiling princess, and a host of other people for a host of services.

|

Lee No.3 Pty Ltd

Trading since 1961 ACN: 005 204 599 ABN: 40 005 204 599 |

For more information please contact Ian Lee on 0428 507 408 [email protected] |

PO Box 614

KYNETON 3444 VICTORIA, AUSTRALIA |